Category

Stock Code

7000FLA

- PCD cutting edges and long tool life.

-Ideal for high chip volume applications.

-Production option in desired diameter and length.

-Made for high speed aluminum machining.

-Up to ten times higher productivity compared to carbide end mills.

-Sharp cutting edges and special helical form guarantee excellent surface quality.

-Ideal for high chip volume applications.

-Production option in desired diameter and length.

-Made for high speed aluminum machining.

-Up to ten times higher productivity compared to carbide end mills.

-Sharp cutting edges and special helical form guarantee excellent surface quality.

Milling diameter: 16 mm – 25 mm

Number of sides: 3

Number of sides: 3

Side milling cutters are a specialized type of cutter used for machining workpieces with deep cavities or complex geometries. Their long, spiral-neck design provides greater reach for deeper cutting operations during machining. These cutters are typically used on CNC machines and are preferred for side milling operations on workpieces requiring high precision. This design allows better access to the depths of the workpiece and reduces vibration when cutting into the interior of the workpiece. Side milling cutters with internal cooling effectively deliver coolant to the interior of the workpiece, controlling heat generated during machining and improving tool performance. The use of these cutters is crucial for achieving high-quality results when machining more complex and precise workpiece geometries. They are particularly preferred in high-precision applications frequently used in industries such as aerospace, automotive, and medical devices.

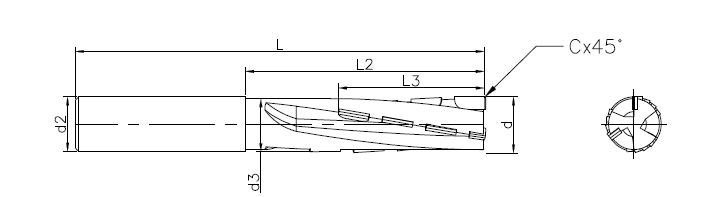

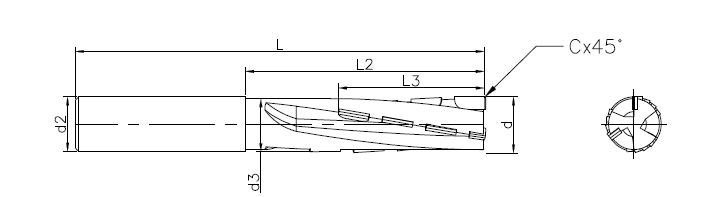

| d | d2 | d3 | L | L3 | L2 | CX45° | Z |

| 16 | 16 | 15 | 100 | 30 | 50 | 0.15 | 3 |

| 20 | 20 | 19 | 100 | 30 | 50 | 0.15 | 3 |

| 25 | 25 | 24 | 110 | 30 | 50 | 0.15 | 3 |

Be the first to comment on this product!